Shell Corena Compressor Oils

Shell is a world leading company in the development of air compressor lubricants. We have our own inhouse product R&D capabilities spread over 3 continents (Germany, China, Japan, and USA) which enable us to be close and collaborate with major compressor OEMs and develop innovative lubricants to satisfy the needs of the equipment operators and deliver world class solutions. Shell Corena oils are well known for decades, and their performance has been constantly demonstrated in real-life applications to help reduce the likelihood of your equipment letting you down.

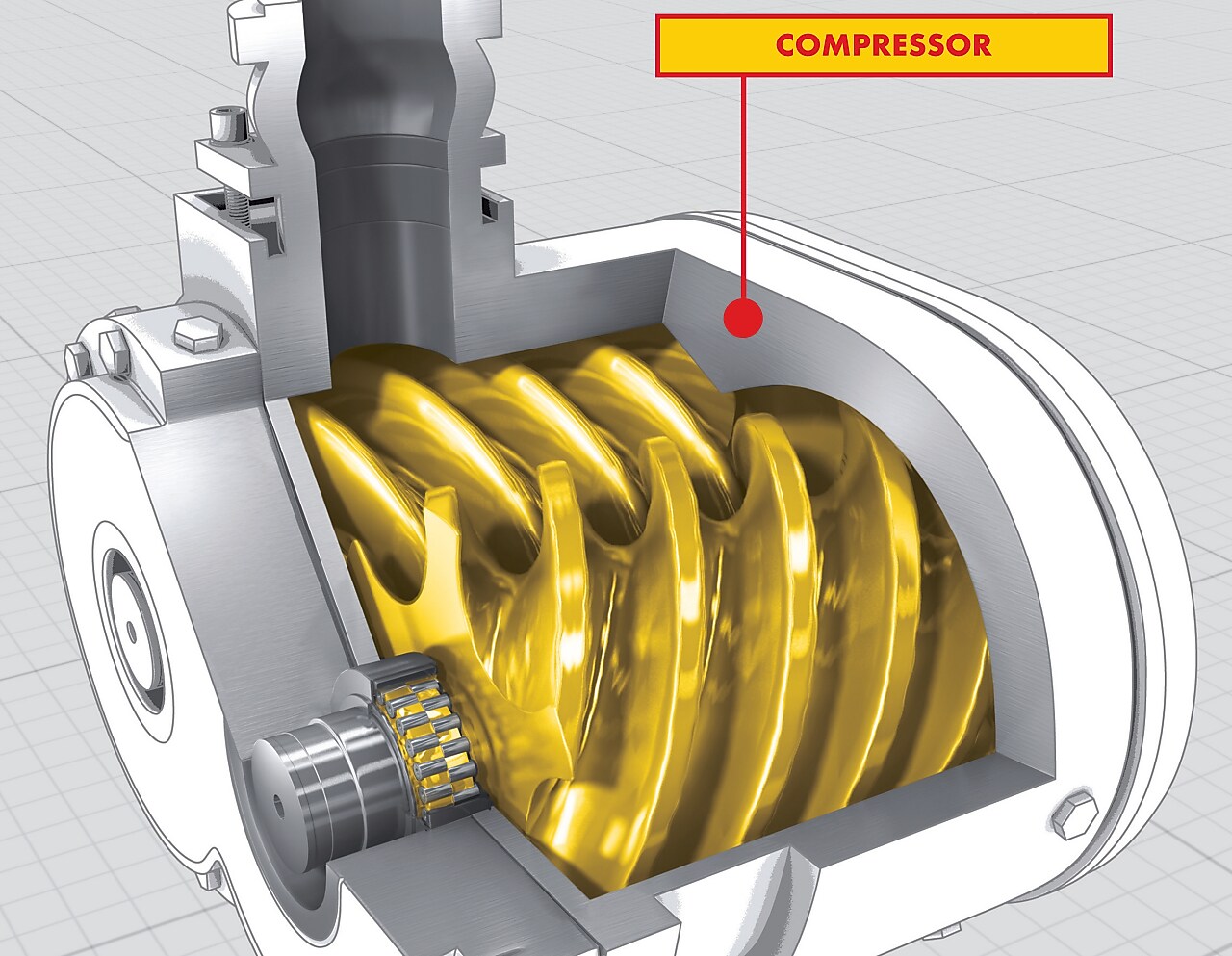

From rotary vane and screw to reciprocating (piston) air compressors, the Shell Corena range of oils covers a wide range of compressor types to meet the challenges of a wide range of air compressors and applications and has designed a portfolio of oils that enables you to choose a product to match your needs.

SHELL CORENA “R” RANGE has been designed for rotary vane and screw air compressors for use in stationary and mobile air compressors.

SHELL CORENA “P” RANGE has been designed for reciprocating (piston) air compressors for safe and reliable operation in demanding high-pressure applications.

Customers looking for longer oil life, better protection and system efficiency should choose Shell Corena S4 R based on their application and equipment specifications.

Innovative air compressor oils that elevate operations

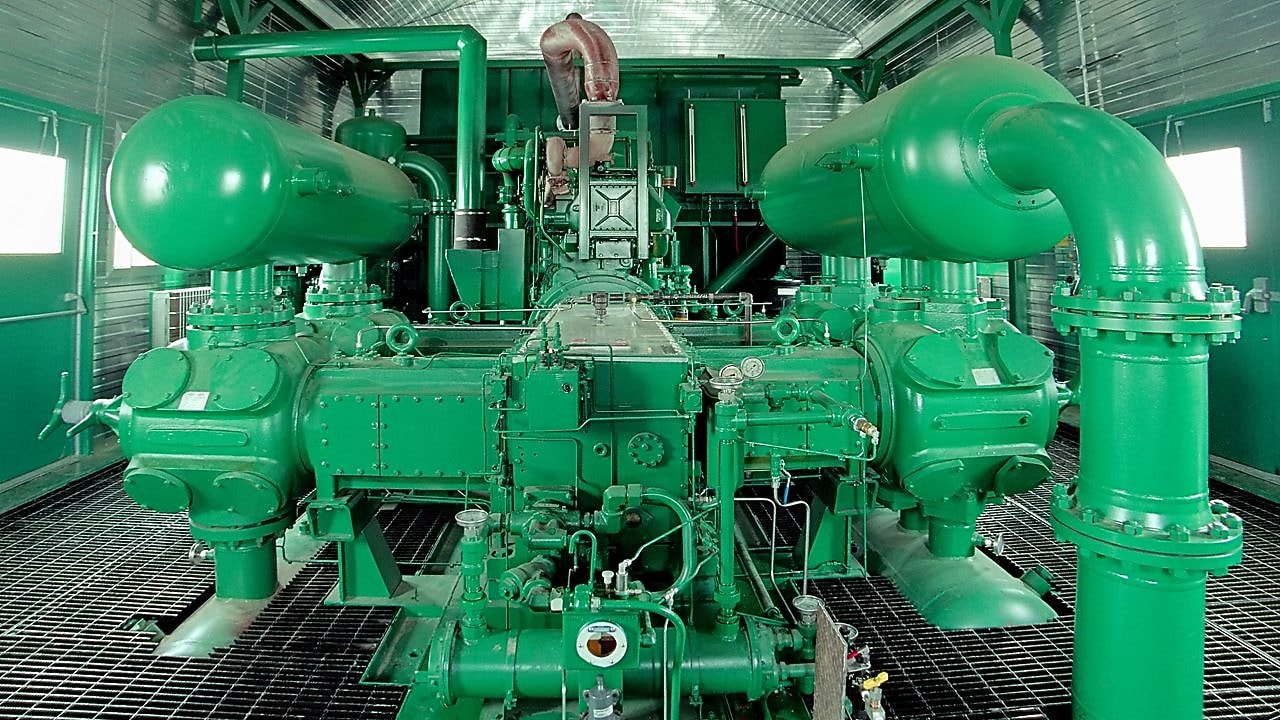

Because of their high power-to-volume or power-to-weight ratio, air compressors are a cost-effective and highly efficient option across a range of manufacturing-based industries, helping to deliver the power that is critical for production.

But only a well-maintained air compressor is likely to realise these potential cost and efficiency benefits over its lifetime. That makes your choice of compressor oil an important one, especially since compressors are becoming increasingly compact, forcing less oil to work harder, for longer.

Developed alongside both customers and equipment manufacturers, our Shell Corena range of compressor oils has been designed to meet the industry requirements needed to overcome real-world challenges. With performance you can rely on, protection that’s been real-world tested, and technology that is at the forefront of industry innovation, find an oil that works smart as well as hard.

Real-world value delivery

After switching to synthetic compressor oil Shell Corena S4 R, customers reported the following benefits:

- 2× longer oil-drain intervals compared with conventional oils

- 3× longer between compressor overhauls in a demanding cement application

- greater efficiency and lower operating temperatures by avoiding oil thickening

Reducing costs by extending oil-drain interval

A cement company switched to fully synthetic Shell Corena S4 R 68 and used the Shell LubeAnalyst service to monitor oil performance. This helped the company to achieve a 2.5x increase in oil-drain interval, from 2,000 to 5,000 hours.

Based on lower operating costs resulting from reduced oil consumption and increased uptime, the company has reported estimated annual savings of US$511,000.

Operating without interruption

The longer an oil's life, the less fluid maintenance your equipment requires, so it can continue to operate without interruption.

Shell Corena synthetic oils have up to 10,000 hour oil-drain intervals, even in high-temperatures and high-humidity regions.

Shell Corena family range

Hours of engineering and decades of expertise go into the design and development of your air compressors, so why limit that potential by choosing an oil that’s not fit for purpose? From rotary vane and screw to reciprocating (piston) air compressors, the Shell Corena range if oils covers a wide range of compressor types.

Find the right Shell Corena Compressor Oil

Advanced

Shell Corena S4 R

Synthetic

• Polyalphaolefin (PAO) based

• Improved efficiency

• Severe applications

• Deposit control

• Extra long life

• ISO 6743-4 L-DAJ

- Compressor type

- Rotary vane and screw air compressor oil

- Application

- Factory / machine, Mobile compressors, High temperature

- Viscosity

- 32 46 68

Advanced

Shell Corena S4 P

Synthetic

• Extra long life

• Improved efficiency

• Severe applications

• DIN 51506 VDL ISO/DP 6521-1-1-L-DAB - severe duty

• ISO 6743-3 L-DAB - Severe duty

- Compressor type

- Reciprocating (piston) air compressor oils

- Application

- Factory / machine, Mobile compressors, High temperature

- Viscosity

- 68 100

Premium

Shell Corena S3 R

• High-quality hydrotreated mineral base oils

• High efficiency

• Long life

• ISO 6743-3 L-DAH

- Compressor type

- Rotary vane and screw air compressor oil

- Application

- Factory / machine, Mobile compressors, High temperature

- Viscosity

- 46 68

Premium

Shell Corena S3 RX

Synthetic

• Shell gas-to-liquids (GTL) technology

• Excellent system efficiency

• Long life

• ISO 6743-3 L-DAJ

- Compressor type

- Rotary vane and screw air compressor oil

- Application

- Factory / machine, Mobile compressors, High temperature

- Viscosity

- 46 68

Mainstream

Shell Corena S2 P

• Reliable protection

• Standard-life applications

• DIN 51506 VBL

• ISO 6743-3 L-DAA - Normal duty

- Compressor type

- Reciprocating (piston) air compressor oils

- Application

- Mobile compressors, Factory / machine, High temperature

- Viscosity

- 68 100 150

Real-world case studies

Metals case study

Supported by Shell technical training, Shell Corena S4 R 46 saw this metals plant increase its oil-drain intervals by 12.5% – find out more.

General Manufacturing case study

Learn how Shell Corena S4 R 68 and Shell LubeAnalyst combined to help this manufacturing company reduce its oil consumption.

Cement case study

Thanks to a 70% reduction in maintenance time, Shell Corena S3 R 46 helped this cement company to estimated annual savings of $871,000.

Marine case study

Discover how Shell Corena S4 P contributed to a doubling in interval time between air compressor overhauls, cutting waste oil volume and supporting maintenance practices.

Disclaimers

*Data reported by specific customers. Actual oil-drain intervals will vary depending on specific equipment types, and working and environmental conditions.

More from Shell Lubricants Solutions

Discover our Services for Industrial Manufacturing

The Shell LubeAdvisor service is delivered through highly trained Shell technical staff consisting of office-based technical helpdesks and field-based lubrication engineers. In addition, there are a number of helpful and convenient tools for you to use, with the complete Shell LubeAdvisor service offering you a wealth of engineering, technical and application knowledge.