Shell Omala Gear Oils

Drive system efficiency, increase productivity and reduce your total cost of ownership with the Shell Omala range of gear oils designed to help your gearboxes work harder for longer.

Extend gearbox life with enhanced protection from wear, corrosion and rust across a wide range of applications. From remote locations to extreme temperatures, the Shell Omala range is formulated to help you get the most out of your equipment in even the most challenging conditions. Longer oil life also helps you to extend service intervals and improve productivity while reducing maintenance-associated costs. With Shell Omala you maximise their potential and keep the wheels of industry turning smoothly. From industrial manufacturing to mining, the Omala family offers you the versatility needed for any operation, delivering performance and to meet any industrial gearbox need. Explore the Omala range today to extend your maintenance-free operations.

Shell Omala “G” Range has been designed for industrial spur and bevel gear applications from standard to demanding high-load and extended-duty applications.

Shell Omala Specialty Range has been designed for industrial spur and bevel gears for special applications such as extra shock-load protection or particulate contamination control.

Shell Omala “W” Range has been designed for industrial worm-drive applications from standard to demanding high-load and extended-duty applications.

Shell Omala "Wind" Range specific designed gear oil for Wind power.

Discover Shell Omala Gear Oils

Advanced

Omala S4 GXV Plus - Simplify your portfolio and reduce your maintenance cost with multiple key OEM approvals

A new oil for current and future gearbox technologies. We have designed the new Shell Omala S4 GXV Plus advanced full synthetic industrial gear oil to meet the needs of current and future gearboxes. It passes the specific and demanding testing requirements of latest global industry standards leading gearbox manufacturers and is approved by manufacturers including SEW-EURODRIVE, Flender and Sumitomo.

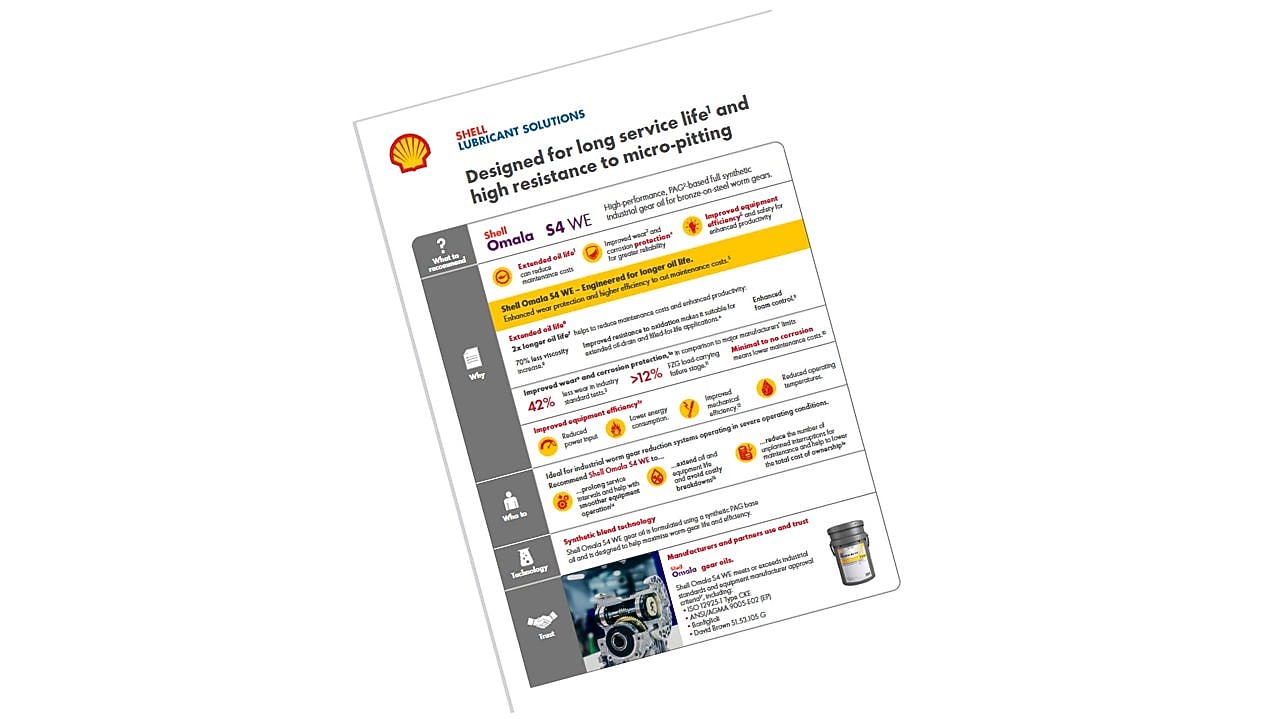

Omala S4 WE

High-performance, PAG-based full synthetic industrial gear oil for bronze-on-steel worm gears. Uncontrolled oxidation can reduce oil life and lead to sludge, increased viscosity and corrosion, which can cause gear and bearing wear, smaller bearing clearances, plugged lines and blocked filters. Shell Omala S4 WE is a PAG-based fluid with improved resistance to oxidation, which makes it suitable for extended oil-drain intervals and filled-for-life applications.5 In industry standard tests,6 Shell Omala S4 WE has more than 2× longer oil life compared with mineral oils7 and 70% less viscosity increase compared with the DIN industry limit.8

Shell Omala family range

Creating value by keeping industrial spur and bevel gearboxes and worm gears operating efficiently for longer, even in severe applications and challenging operating conditions.

Find the right product for your application

Advanced

Shell Omala S4 GXV Plus

• Micropitting resistance / performance

• High temperature

• Low / Medium load

• High load

• Longer Life & Extra Protection

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears, Gear oils with SEW Approval, Shell Gear oils for Wind turbines, Shell Gear oils for Motorized wheel for mining haul trucks, Gear oils for Robotics

- Viscosity

- 150, 220, 320, 460, 680

Advanced

Shell Morlina S4 B

• High temperature

• Low / Medium load

• Synthetic PAO as fill or Al bronze gear

• Synthetic PAG as fill

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears, Shell Gear oils for Industrial Worm gears

- Viscosity

- 150, 220, 320

Advanced

Shell Omala S5 Wind

• Main Gearbox

• Yaw and pitch Gearbox

• Longer Life & Extra Protection

• Formulation - PAO based

- Application

- Shell Gear oils for Wind turbines

- Viscosity:

- 320

Advanced

Shell Panolin S4 Gear

• Standard

- Application

- Biodegradable Gear oil

- Viscosity

- 68, 100, 150

Advanced

Shell Panolin S4 Gear EAL

• Eco Label Required

- Application

- Biodegradable Gear oil

- Viscosity

- 68, 100, 150, 220, 320

Advanced

Shell Omala S4 WE

• Internal backstop (non-EP) required

• High temperature

• Synthetic PAG as fill

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears, Shell Gear oils for Industrial Worm gears, Shell Gear oils for Wind turbines, Gear oils for Robotics

- Viscosity

- 150, 220, 320, 460, 680

Premium

Shell Morlina S3 BA

• Internal backstop (non-EP) required

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears

- Viscosity

- 460, 320

Premium

Shell Omala S3 GP

• High load

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears

- Viscosity

- 220, 320, 460, 680, 1500

Mainstream

Shell Omala S2 GX / Plus

• Micropitting resistance / performance

• Low / Medium load

• High load

• Standard

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears, Gear oils with SEW Approval, Shell Gear oils for Motorized wheel for mining haul trucks

- Viscosity

- 68, 100, 150, 220, 320, 460, 680

Mainstream

Shell Morlina S2 B

• Internal backstop (non-EP) required

- Application

- Shell Gear oils for Helical, spur, bevel and planetary gears

- Viscosity

- 32, 46, 68, 100, 150, 220, 320, 460, 680

Mainstream

Shell Omala F Wind

• Standard

- Application

- Shell Gear oils for Wind turbines

- Viscosity:

- 320

More from Shell Lubricants Solutions

Discover our Services for Industrial Manufacturing

The Shell LubeAdvisor service is delivered through highly trained Shell technical staff consisting of office-based technical helpdesks and field-based lubrication engineers. In addition, there are a number of helpful and convenient tools for you to use, with the complete Shell LubeAdvisor service offering you a wealth of engineering, technical and application knowledge.

Disclaimers:

1 All data shown is derived from tests in laboratories at Shell Lubricant Solutions or partners using accepted standard methods, taken from the Shell Omala product range brochure

2 Lubricant life depends on the operating conditions, and mixing Shell Omala S4 WE with other PAG-based fluids may reduce oil life. PAG-based fluids should never be mixed with mineral oils.

3 RPVOT, modified ASTM D2272 test at 120°C.

4 Compared with conventional oil such as Shell Omala S1 W.

5 Viscosity increase percentage after test D2892 at 121°C over 312 h.

6 Four-ball wear test, 100 min, 1,500 rpm, 20 kg, ambient temperature.

7 FZG is the Institute of Machine Elements – Gear Research Center. A/16.6/90, ASTM D445, IP71.

8 ASTM D665A/ISO 7120/IP 135, 4 h at 60°C.

9 Based on Shell internal competitor benchmarking tests.