Shell Morlina Bearing and Circulating Oils

Industrial equipment can differ considerably often operating beyond the original design parameters and in changing and harsh environments. Equipment reliability and performance is the key to quality of products and profitability. Shell offers a wide range of bearing and circulating oils, from robust, reliable products to fully synthetic products fortified with extreme pressure (EP) additives. There are also speciality products designed to cope with hot, wet or dusty environments, or high-precision operations.

Shell Morlina family of products has been developed to protect and enhance the lubrication of bearings and key system components ensuring performance when faced with contamination such as water and hot dusty environments. The specialised range offers bearing and circulating oils with and without extreme pressure additive technology and mineral to synthetic base oil offering improved oxidation performance.

The Shell Morlina “B” range - bearing and circulating oils with a range of protection and performance levels for a wide range of industrial applications.

The Shell Morlina “BL” range - extra-low-viscosity grades for use in high-speed machine spindle applications.

The Shell Morlina “BA” and “BX” ranges - speciality bearing and circulating oils with enhanced characteristics for use in demanding applications in the metal sector.

From protection against corrosion to improvements in system efficiency, the Shell Morlina range of bearing and circulating oils helps you to maximise equipment uptime, increase productivity and reduce maintenance costs. It has a proven track record in real-life applications, with the different oils and lubricants recommended or approved by leading original equipment manufacturers (OEMs) and users around the world.

Keeping the world of bearings turning with Shell Morlina oils providing performance benefits in the following areas:

- Lubrication systems which are susceptible to high levels of water contamination

- For bearing and circulating oil systems containing plain or rolling element bearings

- For industrial gearboxes, enclosed spur, helical, bevel and worm gearboxes where the use of a non-EP, rust- and oxidation-inhibited oil is approved

- For a wide range of reciprocating compressors, for both frame systems and compressor

- For cylinders, and in special applications in screw compressors for gas compression

Explore the Shell Morlina range

Performance you can count on. Shell Morlina oils have been designed and developed in close co-operation with customers and equipment makers and have a proven track record in real-life applications. They are recommended or approved by leading equipment makers and users around the world, so you can be assured that they will not let you down.

Discover Shell Morlina Bearing and Circulating Oils Products

Advanced

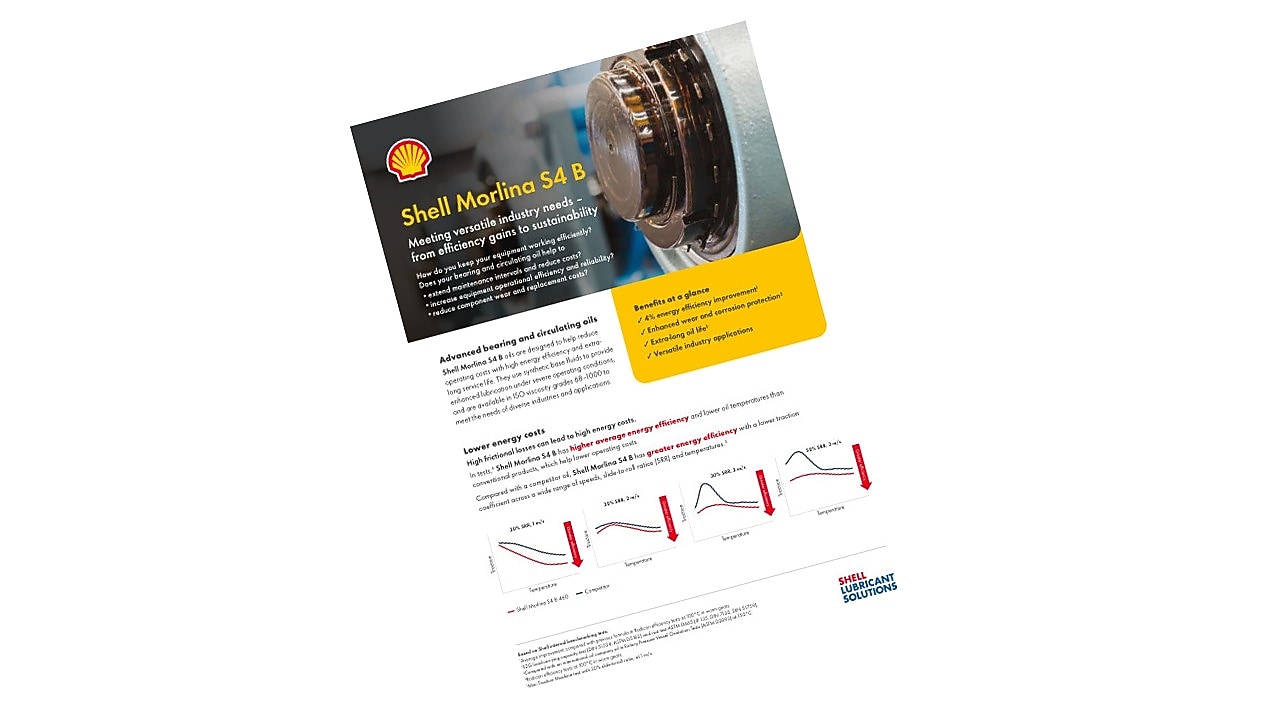

Shell Morlina S4 B

Meeting versatile industry needs – from efficiency gains to sustainability. Shell Morlina S4 B oils are designed to help reduce operating costs with high energy efficiency and extralong service life. They use synthetic base fluids to provide enhanced lubrication under severe operating conditions and are available in ISO viscosity grades 68–1000 to meet the needs of diverse industries and applications.

Premium

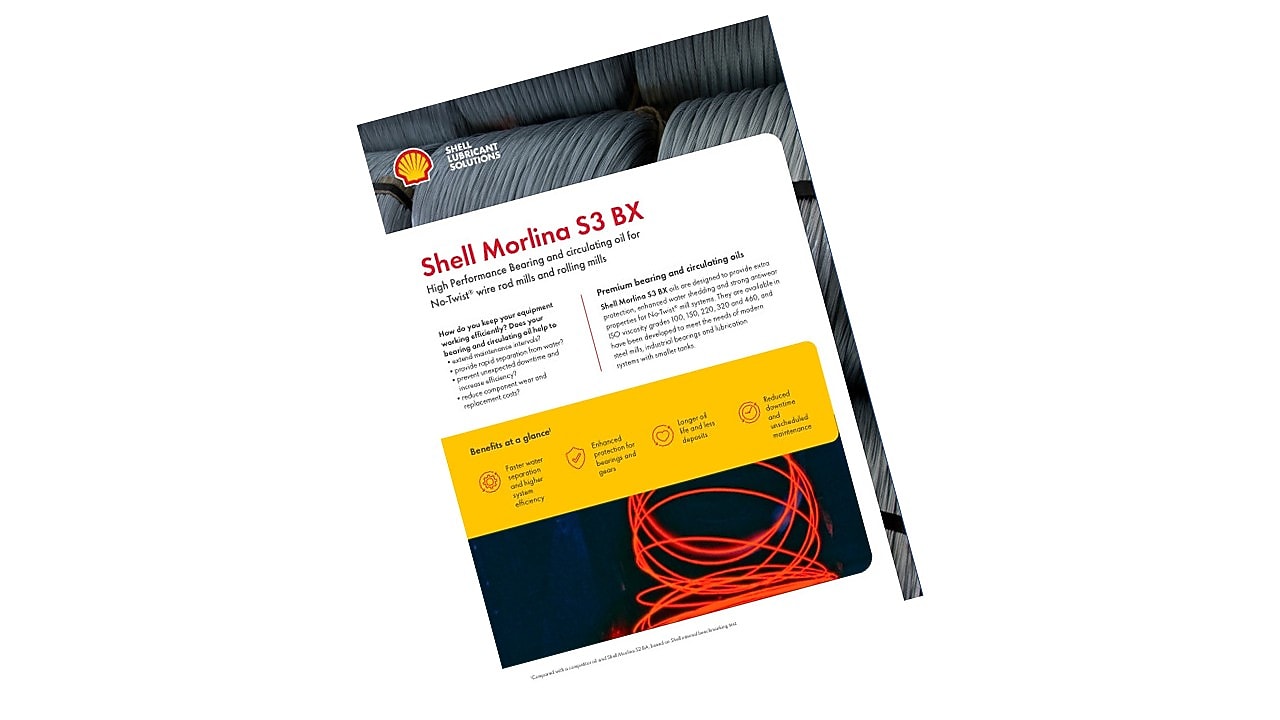

Shell Morlina S3 BX

High Performance Bearing and circulating oil for No-Twist® wire rod mills and rolling mill. Shell Morlina S3 BX oils are designed to provide extra protection, enhanced water shedding and strong anti-wear properties for No-Twist® mill systems. They are available in ISO viscosity grades 100, 150, 220, 320 and 460, and have been developed to meet the needs of modern steel mills, industrial bearings and lubrication systems with smaller tanks.

Premium

Shell Morlina S2 BA

The new-generation Shell Morlina S2 BA bearing and circulating oil is for the lubrication of Primetals (Morgan) NoTwist® rod mill systems and will deliver optimum value through extra wear protection, water shedding and a special application bearing and circulating oil.

Find the right product for your application

Advanced

Shell Morlina S4 B

- Extra-long life

- Extra protection

- Severe applications

Key approvals – Approved or recommended by:*

DIN 51517 – Type C, CL, CLP, ISO 12925-1 Type CKB, CKC, CKD, Siemens/VIA and SMS Group, Staubli Piccanol, Nord Gear, Marley, Renold Gears, David Brown, Cone Drive, Formsprag, Primetals Morgoil®, Valmet (Metso) (paper machine oils) and Voith VN 108

- Application

- Compressor cylinder, Screw compressor and blowers, Gearbox and reducer (non-EP and warm), Paper machine circulating system, No-Twist® wire rod mill bearings

- Operational conditions

- Worm gear, Roller bearing, Enclosed gear, High load, Extreme high temperature

Premium

Shell Morlina S3 BX

Technology: Conventional, zinc free

ISO viscosity grades : 100 and 150

Benefits:

- Zinc free

- Extra protection

- Enhanced water shedding

- Good anti-wear properties

Key approvals – Approved or recommended by:*

DIN 51517 – Type C, CL, CLP, ISO 12925-1 Type CKB, CKC, Danieli Standard 0.000.001, Rev. 15 – Oil Type 21-24, Primetals No-Twist® Spec. MMC40003, and SMS X-Roll Oil Bearing SN-180-2 and SN-180-3

- Application

- No-Twist® wire rod mill bearings

- Operational conditions

- Roller bearing, Plain bearing

Premium

Shell Morlina S3 BA

Technology: Conventional, non-EP

ISO viscosity grades : 320 and 460

Benefits:

- Extra-long life

- Enhanced water shedding

- General journal bearing oil

Key approvals – Approved or recommended by:*

DIN 51517 – Type C, CL, ISO 12925-1 Type CKB, Primetals Morgoil® – Advanced Lubricant New Oil (Rev 2.4), Danieli SuperDemulsifiable Oil 6.124249.F, Danieli Standard Oil 6.124249.F

- Application

- Gearbox and reducer (non-EP and warm)

- Operational conditions

- Plain bearing, Roller bearing, Wet conditions

Premium

Shell Morlina S2 BA

Technology: Conventional, anti-wear

ISO viscosity grades : 100 - 150 - 220 - 320 - 460

Benefits:

- Reliable protection

- High-speed applications

Key approvals – Approved or recommended by:*

ISO 6743-2 Type L-FC, L-FD, Fives Group Machine P-62 (ISO 5, 10) and Cincinnati Machine P-45 (ISO 22)

- Application

- No-Twist® wire rod mill bearings, Bodymaker machines - Can manufacturing

- Operational conditions

- Roller bearing, Plain bearing

Mainstream

Shell Morlina S2 B

Technology: Conventional, mild EP

ISO viscosity grades : 32 - 46 - 48 - 100 - 150 - 220 - 320 - 460 - 680

Benefits:

- Reliable protection

- High-speed applications

Key approvals – Approved or recommended by:*

DIN 51517 – Type C, CL, ISO 12925-1 Type CKB Primetals Morgoil® – New Oil (Rev. 1.1), Danieli Standard Oil 6.124249.F

- Application

- Compressor cylinder, Screw compressor and blowers

- Operational conditions

- Roller bearing, Plain bearing, Wet conditions

Mainstream

Shell Morlina S2 BL

Technology: Conventional, anti-wear

ISO viscosity grades : 5 - 10 - 22

Benefits:

- Reliable protection

- High-speed applications

Key approvals – Approved or recommended by:*

ISO 6743-2 Type L-FC, L-FD, Fives Group Machine P-62 (ISO 5, 10) and Cincinnati Machine P-45 (ISO 22)

- Application

- High-speed applications (spindles)

- Operational conditions

- Roller bearing, Plain bearing

More from Shell Lubricant Solutions

Discover our Services for Industrial Manufacturing

The Shell LubeAdvisor service is delivered through highly trained Shell technical staff consisting of office-based technical helpdesks and field-based lubrication engineers. In addition, there are a number of helpful and convenient tools for you to use, with the complete Shell LubeAdvisor service offering you a wealth of engineering, technical and application knowledge.