Shell Tellus Hydraulic Oils

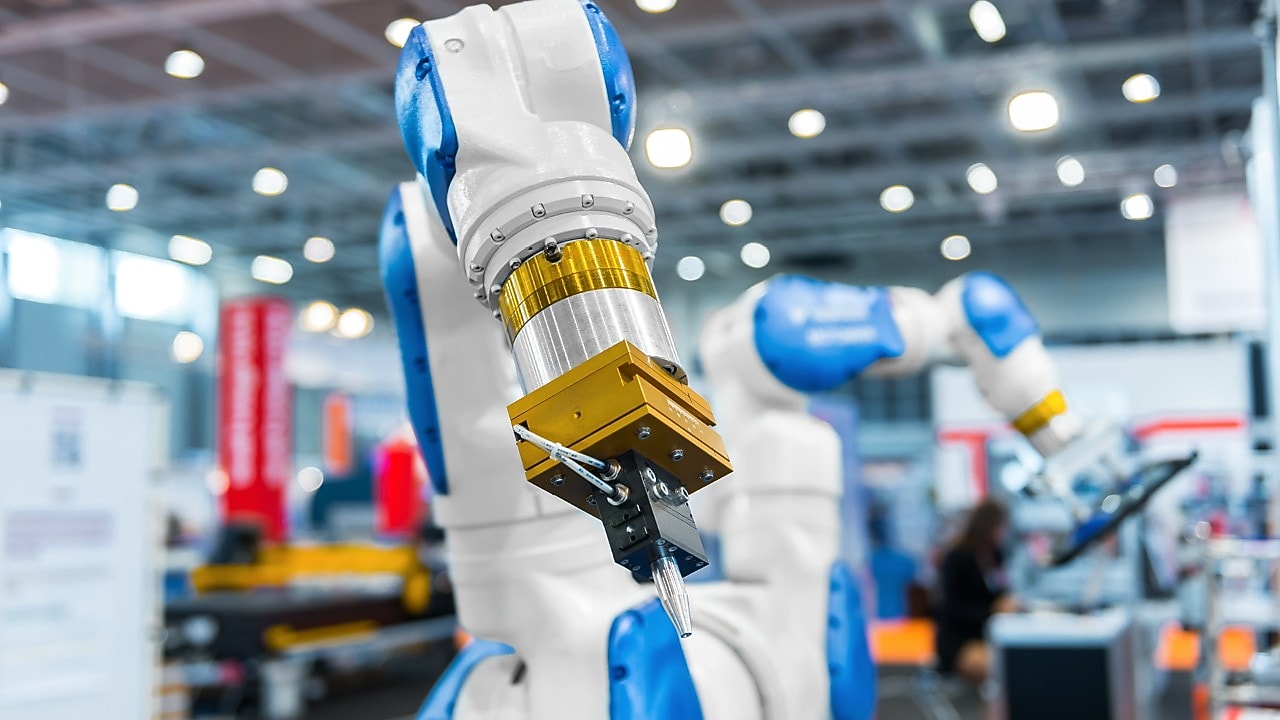

Shell offers a full range of hydraulic fluid solutions for mobile and stationary equipment designed to meet all challenges for a wide range of hydraulic applications such as presses, pumps, injection moulding machines, cranes, excavators, forklifts and for various Industries like Industrial Manufacturing, Plastic, Steel, Cement, Mining, Construction and Agriculture.

Supported by extensive OEM approvals and product acceptance the Tellus synthetic range provides a longer oil life, lowers maintenance costs and increases energy efficiency and provides environmental and safety improvements compared to standard mineral based hydraulic oils.

The "M" range has been designed with focus on industrial manufacturing and stationary machine use, in the Shell naming structure the "M" stands for maintenance. Products in this range are mainly according to DIN 51524-2, HLP.

The "V" range has been designed for mobile machine use covering a wide range of operating conditions. in the Shell naming structure the "V" stands for versatile. Products in this range are according to DIN 51524-3, HVLP.

Discover Shell Tellus Hydraulic Oils

Advanced

Shell Tellus S4 VE

Find out how you can extend equipment life, lower your maintenance costs and boost hydraulic performance with the latest oil technology.

Shell Tellus S4 VK

Protect your equipment operating in cold climates with a high-performance, all-season hydraulic fluid based on GTL technology and featuring advanced anti-wear properties

Premium

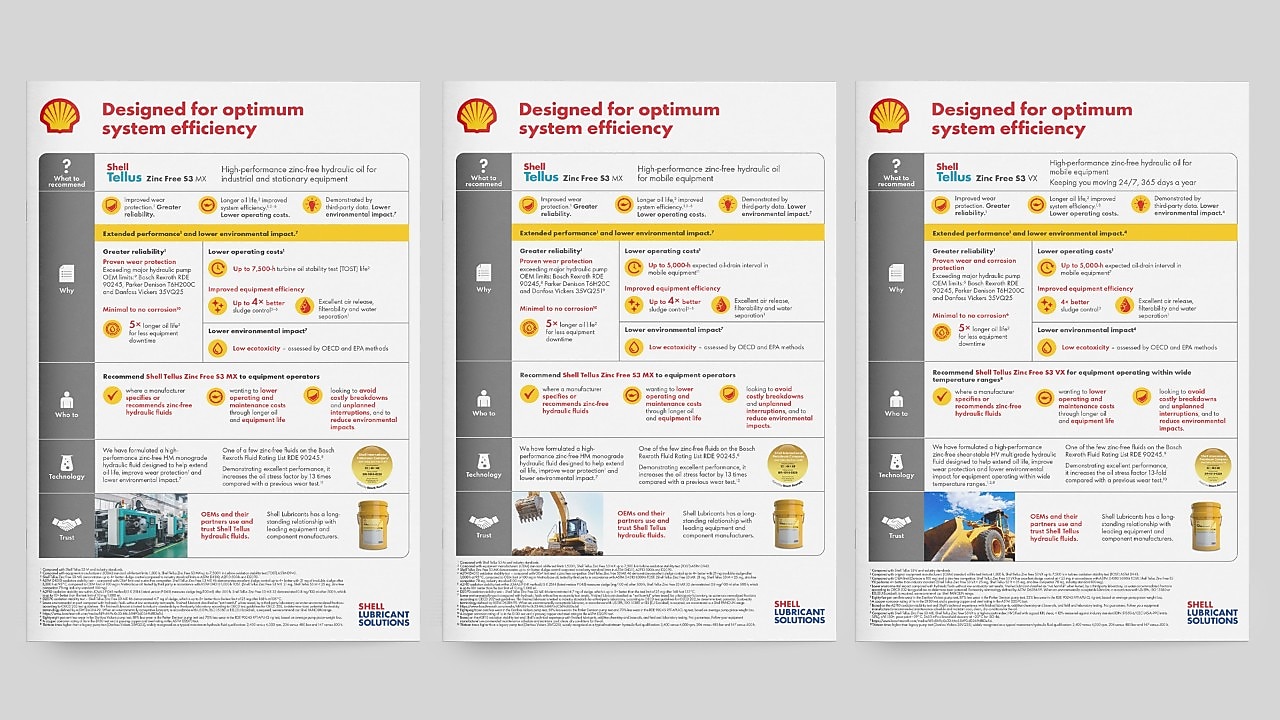

Shell Tellus Zinc-Free S3 MX and VX

Where manufacturers specify or recommend zinc-free hydraulic oil. For greater reliability, one of a few high-performance zinc-free fluids on the Bosch Rexroth fluids rating list RDE 90245.

Shell Tellus S3 VS

Overcoming stick-slip friction with the right fluid formulation

Stick-slip friction is a common problem within hydraulic systems that can reduce the efficiency of your operations and even affect your people’s safety. Discover how using the right formulation for your hydraulic fluids can reduce stick-slip friction – along with the associated noise, vibrations and potential safety risks.

Read the transcript

Read the transcript

Title: {Shell Tellus Zinc Free S3 MXVX Video_Transcript_Benefit of Bosch Rexroth August 2025}

Duration: {3:14} minutes

Description

{Shell’s new Shell Tellus Zinc Free S3 MX exceeds Bosch Rexroth requirements and Shell Tellus Zinc Free S3 VX fluids are recommended for mobile equipment in a wide range of temperatures.}

{Based on third-party OECD and EPA text data, our new zinc-free fluids reduce ecotoxicity and deposit formation, improve metal and seal compatibility, lower your environmental impact and help protect your assets.}

{Shell Tellus Zinc Free S3 MXVX Video_Transcript_Benefit of Bosch Rexroth Feb 2025}

[Background sound effect]

{Uplifting background music that continues to almost the end of the video.}

[Video footage]

{The screen is yellow; text appears in the centre. The words slowly get bigger.}

[Text displays]

{The importance of selecting zinc-free fluids that

meet the challenging Bosch Rexroth standard}

[Animated sequence]

{The words disappear, leaving the screen as a yellow rectangle. The rectangle shrinks towards the vanishing point and a diagram of laboratory equipment, inside a red-bordered rectangle, takes up most of the screen. The yellow rectangle has become a yellow square with a red border superimposed over the centre of the diagram. Inside the square are the letters “Zn” in a red circle diagonally crossed through by a red line. Around the circle are the atomic number for zinc (30), the word “Zinc” and the atomic weight for zinc (65.38). A partial yellow rectangle appears from the bottom-right corner and on it containing text that appears as if being typed.}

[Voiceover]

{Do you opt for zinc-free hydraulic fluids to maintain equipment performance …}

[Text displays]

{reducing deposit formation}

[Voiceover]

{… by reducing deposit formation and meet environmental regulations by reducing ecotoxicity?}

[Animated sequence]

{Meanwhile, a drawing of an excavator in a red-bordered rectangle moves quickly from the right to cover the previous drawing, the yellow box with a red border at the centre changes to contain a drawing of a hydraulic cylinder with a shimmering star representing cleanliness appearing next to it inside the smaller box. Red circles appear on the excavator identifying the bucket cylinder, arm cylinder and boom cylinder. At the same time, text appears as a footnote below the drawing of the excavator.

[Text displays]

{1Compared with conventional HM hydraulic fluids}

[Animated sequence]

{The yellow central hydraulics graphic turns into a liquid drop inside a blue-bordered rhombus. The red dots disappear from the excavator. The text in the yellow bottom-right box disappears and is replaced by new text.}

[Text displays]

{reducing ecotoxicity1}

[Animated sequence]

{The liquid drop rhombus shrinks towards the vanishing point. A white rectangle appears from the right and quickly covers the excavator rectangle. The bottom-right yellow box disappears. Two containers, one on the left marked with the same crossed-out “Zn” with accompanying information mentioned above and one on the right, appear and grow in size. Four different quality-control symbols appear vertically aligned in between the two containers. They split up, the top two ones moving left to be next to the zinc-free container and the bottom two moving towards the unmarked container. A red question mark appears above each container. Then the two bottom-right quality control symbols move left to vertically align with the top two symbols next to the zinc-free container. The screen goes white and text appears as if being typed.}

[Voiceover]

{Are you put off, owing to concerns about wear protection and potential impact on warranties? The truth is that not all hydraulic oils are the same and not all zinc-free fluids have data to back ecotoxicity assumptions. }

[Text displays]

{So how do you decide

which fluid to select?}

[Animated sequence]

{A red-bordered rectangle moves in quickly from the right to cover this text. Inside the rectangle is a drawing of a hydraulic cylinder, which pumps, and a red and yellow gauge. Another partial yellow box appears in the bottom right corner inside which text appears as if being typed.}

[Voiceover]

{So how do you decide which fluid to select? Today’s hydraulic fluids need to work harder, for longer, with lower environmental impact.}

[Text displays]

{work harder, for longer2}

[Animated sequence]

{Meanwhile, corresponding footnote text appears below the hydraulics rectangle.}

[Text displays]

{2Increasing operating pressures, speeds, oil circulation

temperatures and power density. Bosch Rexroth reports

that power-to-weight ratio for axial piston pumps and

motors more than doubled over the last few decades.}

[Animated sequence]

{The same liquid drop inside the rhombus appears below the cylinder. The cylinder continues to pump.}

[Text displays]

{3Compared with hydraulic fluids

without low ecotoxicity test results.}

[Animated sequence]

{At the same time, new text replaces the previous text in the yellow text box.}

[Text displays]

{lower environmental impact3}

[Voiceover]

{Equipment manufacturers are tightening fluid requirements to meet the needs of newer designs and today’s operating conditions.}

[Animated sequence]

{The cylinder continues to pump and the liquid rhombus shrinks. The yellow box, its text and the footnote text disappear. The rectangle at the centre is replaced by a slightly larger rectangle, inside which is an axial piston unit whose pistons are pumping. Four horizontal yellow lines appear to the right of the drawing and still inside the red-bordered rectangle. The top line is thicker than the others. The word “performance” appears to the left of the lines, at a 90-degree angle. On the bottom line “DIN ISO” appears.

[Text displays]

{

DIN ISO}

[Voiceover]

{They need fluids with performance beyond established DIN and ISO standards. To help, Bosch Rexroth has developed tougher tests that are scientifically sound, standardised and independent. Fluids are rigorously tested at high loads over several hundred operating hours, putting them under 13 times more stress than existing standards. These tests represent real conditions and have been verified in multiple operations. Results differentiate fluids by showing the severity of wear on the axial piston unit and component compatibility including with seals.}

[Animated sequence]

{On the two yellow lines above “DIN ISO” two red question marks, one on each line, appear.}

[Text displays]

{?

?

DIN ISO}

[Animated sequence]

{The bottom two question marks slightly fade out and a third question mark appears on the top yellow line.}

[Text displays]

{?

?

?

DIN ISO}

[Animated sequence]

{The screen goes white and then a golden circle, shaded to appear like a sphere, appears in the centre, with text inside it.}

[Text displays]

{Shell International

Petroleum Company

Shell Tellus Zinc Free S3 MX

Viscosity grade (s)

32 │ 46 │ 68

Rating number

BR-1010-0320

Bosch Rexroth

Fluid Rating List

RDE 90245}

[Animated sequence]

{Below the circle more text curves around the bottom part of the circle.}

[Voiceover]

Fluids that meet the Bosch Rexroth requirements are included in its Fluid Rating List RDE 90245. They also get a quality label, so you can easily recognise listed fluids. The demand for high-quality, zinc-free hydraulic fluids is increasing, driven by a focus on reducing deposit formation, improving metal and seal compatibility, and lowering environmental impact.}

[Text displays]

{Rated by Bosch Rexroth}

[Animated sequence]

{The circle gets bigger. Then the screen goes white and a red-bordered square appears, on the left. Inside the red square is a drawing of a laboratory flask, with red bubbles inside it and partially obscuring it is a magnifying glass. Beneath it in a yellow box some text appears.}

[Text displays]

{scientifically sound}

[Animated sequence]

{A second box appears to the right of the first. Inside it is a drawing of three overlapping pieces of paper with four lines on them; the top-most line is red. Beneath this box text appears.}

[Text displays]

{standardised}

[Animated sequence]

{A third red-bordered box appears to the right of the second. Inside it are three arrows, overlapping each other. A red arrow points to the left and the other two black arrows point upwards and to the right, respectively. Beneath this box in a yellow box text appears.}

[Text displays]

{independent}

[Animated sequence]

{The screen goes white. A drawing of a fluid test bench inside a red-bordered rectangle moves in from the right to cover the centre of the screen. Text appears above the drawing.

[Text displays]

{fluid test bench}

[Animated sequence]

{Standing to the right of the test bench and facing it is a worker in a hard hat. To the right of them is a large red gauge above which is a red “0” and above that in a yellow box is text.}

[Text displays]

{operating (hrs)

[Animated sequence]

{The arrow on the red gauge rapidly spins clockwise and the number above it quickly counts upwards from “0” to “510”. The gauge and digits disappear, as do the words “fluid test bench”, and are replaced by digits and a multiplication sign, counting from 0 to 13 with text beneath them. When the digits reach “13” a superscript “4” appears next to the 13 and the 13 shudders as if coming to an abrupt stop.}

[Text displays]

{134×

more stress}

[Animated sequence]

{As the digits turn to 13, footnote text appears below the main rectangle.}

[Text displays]

{413× higher than the legacy pump test (Danfoss Vickers 35VQ25), widely recognised as a typical mainstream hydraulic fluid qualification: 2,400 vs 4,000 rpm; 206 vs 480 bar; and 147 vs 500 h.}

[Animated sequence]

{The same excavator from before inside a red-bordered rectangle appears from the right and covers the previous rectangle. Below it appears footnote text.}

[Text displays]

{5Bosch Rexroth Fluids test video:

youtu.be/os9hLbnf-dU?si=rwgbKsUOXLEEUX_7}

[Animated sequence]

{The gauge from earlier in the animation inside the yellow box appears in the centre of the screen, it is pumping. As the pump rotates and extends to horizontally cover much of the centre of the excavator, a partial yellow textbox appears in the bottom-right corner inside which text appears as if being typed.}

[Text displays]

{verified in multiple operations5}

[Animated sequence]

{The yellow textbox disappears and a red-bordered rectangle appears from the right and moves left to obscure the previous rectangle. Inside it are two pairs of pistons, with a shimmering star on each representing their pristine condition. Above each pair is a gauge the same as the earlier red gauge. Beneath each pair is written text.}

[Text displays]

{High-performance fluid} {Poorly performing fluid}

[Animated sequence]

{The hand on each gauge rotates clockwise around the dial. As it does, the piston pair on the right becomes weathered, losing its pristine star, while the piston on the left retains its pristine condition.}

[Animated sequence]

{The screen goes white. A red-bordered rectangle moves in from the right. Inside it is a drawing of a laboratory technician with a pipette. To their right is a red-bordered box containing a drawing of a fluid test centre. Below that is a large fluid container, which increases in size. As it does so a white tick inside a yellow circle appears next to the container, partially obscuring the fluid test centre.}

[Animated sequence]

{The screen goes white. A red-bordered rectangle appears. Inside it, on the left, is piece of paper with text on it and the same pristine condition star appears to cover the very top right corner of the paper.}

[Text displays]

{Fluid Rating List

RDE90245

Fluid 1 ✔

Fluid 2 ✔}

[Animated sequence]

{The pristine-condition symbol grows and rotates slightly. To the right two more sheets of paper appear, smaller than the first and vertically aligned, showing “Market overview” information. Next to them, two red-bordered yellow boxes appear. The upper contains a drawing of a three-dimensional molecular structure. The lower contains a drawing of a tree. Then the two pieces of paper are crossed out with a red cross each and a partial yellow textbox appears in the bottom right-hand corner, containing text that appears as if being typed.}

[Text displays]

{Fluid Rating List RDE 90245}

[Animated sequence]

{The screen goes white and then a golden circle, shaded to appear as a sphere, appears in the centre, with text inside it.}

[Text displays]

{Shell International

Petroleum Company

Shell Tellus Zinc Free S3 MX

Viscosity grade (s)

32 │ 46 │ 68

Rating number

BR-1010-0320

Bosch Rexroth

Fluid Rating List

RDE 90245}

[Animated sequence]

{Below the circle more text curves around the bottom part of the circle.}

[Text displays]

{Rated by Bosch Rexroth}

[Animated sequence]

{The circle gets larger. Then the circle disappears. Then a red-bordered rectangle appears from the right and moves to the centre of the screen. Inside it appears a display case containing four rows of liquid containers, which get slightly smaller, with red text above them.}

[Text displays]

{High-quality, zinc-free hydraulic fluids}

[Animated sequence]

{To the right of the display case, a graph appears, with “Demand” as its vertical label. A red line appears in the bottom left of the graph and extends, curving up and to the right, towards the top right of the graph.}

[Text displays]

{

}

[Animated sequence]

{The rectangle is replaced by another rectangle, inside which is an axial piston unit whose pistons are pumping. It looks dirty, but as the pistons continue to pump the dirt disappears and a pristine-condition star effect appears. A partial yellow textbox appears in the bottom right-hand corner, in which text appears as if being typed.}

[Text displays]

{reduced deposit formation}

[Animated sequence]

{The pistons continue to pump. Two white ticks inside yellow circles appear on the equipment. And the text changes.}

[Text displays]

{improved seal compatibility}

[Animated sequence]

{A liquid drop inside a rhombus appears to the right of the piston machinery. Footnote text appears below the rectangle.}

[Text displays]

{6Compared with conventional HM hydraulic fluids}

[Animated sequence]

{New text replaces the previous text in the bottom right-hand yellow box.}

[Text displays]

{lower environmental impact6}

[Animated sequence]

{Screen goes white and then two rows of liquid containers appear, with the same crossed-out Zn label mentioned earlier. Then most of the containers disappear, leaving only three. Then a new partial yellow text box appears in the bottom right-hand corner and two more containers disappear. The final one increases in size as text appears in the box.}

[Text displays]

{New Shell Tellus Zinc-Free S3 MX}

[Animated sequence]

{A large white tick in a yellow circle appears next to the sole-remaining container. The container gets bigger. The screen then goes white and a single line of text appears in the centre.}

[Text displays]

{It provides…}

[Animated sequence]

{Screen goes white. Two percentage digits and one digit appear in a line in the centre of the screen, counting upwards from 1% and 1, respectively. Below each number, respectively, text appears.

[Text displays]

{lower wear lower wear FZG failure load stage}

[Animated sequence]

{The left-most digit counts up to “91%”, the central digit to “88%” and the right-hand digit to “12”. As they count upwards, text appears below the right-hand digit text.}

[Text displays]

{12

FZG failure load stage

ISO 32, 46 and 68. FZG (ISO 14635-1), measuring

the scuffing load-carrying capacity of gears at

1,450 rpm through progressive load stages at

15-min intervals until a wear limit is reached.}

[Voiceover]

{But very few zinc-free fluids have been able to pass the Bosch Rexroth tests. New Shell Tellus Zinc Free S3 VX exceeds the Bosch Rexroth requirements. It provides extended wear protection compared with OEM test limits, improved system efficiency through three times faster air release and excellent filterability, and five times longer oil life and up to four times less sludge than OEM standards.}

[Animated sequence]

{As the footnote text appears, more text appears in the partial yellow text box in the bottom right-hand corner of the screen as if being typed.}

[Text displays]

{extended wear protection}

[Animated sequence]

{Screen goes white. In the centre a red “1×” appears, getting steadily larger as it changes to “2×” and then “3×”. As it does a partial yellow textbox appears in the bottom right-hand corner with text appearing as if being typed.}

[Text displays]

{improved system efficiency for

reliable and safe machine use}

[Animated sequence]

{Text appears beneath the “3×”.}

[Text displays]

{faster air

release}

[Animated sequence]

{The “3×” and its accompanying text move to the left. Footnote text appears below it.}

[Text displays]

{7Compared with the industry standard

air release test (ASTM D3427). Exceeds

Danfoss Vickers, Parker Denison and

industry standards for filterability.}

[Animated sequence]

{New text replaces previous text in the bottom right-hand yellow textbox.}

[Text displays]

{excellent filterability7}

[Animated sequence]

{A new digit appears next to the “3×” with text beneath it.}

[Text displays]

{2× longer oil life8}

[Animated sequence]

{Footnote text appears beneath the 2× text and the 2× turns to 3×, then 4× and then 5×.}

[Text displays]

{8Compared with OEM limits. Up to 7,500 h TOST life

(ASTM D943). > 600 min RPVOT (ASTM D2272).

1,250 h in the A2F10 pump test, indicating 5,000 h

ODI. < 30 mg sludge formation (ASTM D4310).}

[Animated sequence]

{A new digit appears to the right of the 5× digit, with text below it. It counts up from “1×” to “4×” in increments of one.}

[Text displays]

{4× less sludge9}

[Animated sequence]

{A footnote appears below the three digits.}

[Text displays]

{9Shell Tellus Zinc Free S3 MX demonstrates up to 4× better sludge control compared to industry standard limits in ASTM D4310, A2F10 500 h, D2070. ASTM D4310 oxidation stability test – compared with OEM limit and a zinc-free competitor. Shell Tellus Zinc Free S3 MX 46 demonstrates excellent sludge control up to 4× better with 21 mg of insoluble sludge after 1,000 h at 95°C, compared with OEM limit 100 mg in Motiva base oil, tested by third party in accordance with ASTM D4310 1,000-h TOST test. (Shell Tellus Zinc Free S3 MX 21 mg, Shell Tellus S3 M < 25 mg, zinc-free competitor 78 mg, industry standard 100 mg.) A2F10 oxidation stability test within JCMAS P 041 method JIS K 2514 (latest version P 045) measures sludge (mg/100 ml) after 500 h, Shell Tellus Zinc Free S3 MX 32 demonstrated 0.8 mg/100 ml after 500 h, which is up to 10× better than the test limit of 10 mg/1,000 ml. D2070 oxidation stability test – Shell Tellus Zinc Free S3 MX 46 demonstrated 4.7 mg sludge, which is up to 5× better than the test limit of 25 mg after 168 h at 135°C.

[Animated sequence]

{Screen goes white. Two new red-bordered boxes appear in the centre of the screen. Inside the one on the left is a drawing of a small planktonic crustacean. On the right is a drawing of a marine mysid shrimp. Inside each box is a white tick in a yellow circle. Beneath the two drawings text appears.}

[Text displays]

{OECD 202 – classified as “not harmful US EPA OPPTS 850.1035 – classified as “not harmful” to

Daphnia magna. marine mysid shrimp.}

[Animated sequence]

{A red-bordered rectangle moves quickly in from the right to obscure the two boxes. Inside the rectangle is the same laboratory equipment from the beginning of the animation. In the bottom right-hand corner of the rectangle is a white tick inside a yellow circle. This rectangle is obscured by another moving in from the right. Inside this is the same excavator from earlier in the animation, with a white tick inside a yellow circle in the bottom right-hand corner. As the excavator covers the screen, its white background slowly changes to four separate representations of the four seasons, from left to right spring, summer, autumn, winter. A much smaller yellow excavator can be seen driving from left to right from summer to autumn and a light-purple silhouette of a dump truck drives from right to centre in the winter section. The screen goes white and then text appears, as if being typed, across the centre of the screen.}

[Voiceover]

{Shell Tellus Zinc Free S3 VX also has OECD and EPA test data to demonstrate low ecotoxicity. The fluid is suitable for stationary and mobile applications. If your mobile equipment operates in a wide range of temperatures, we recommend the Shell Tellus V range, including Shell Tellus Zinc Free S3 VX.}

[Text displays]

{Ask us how Shell Tellus and Shell PANOLIN

hydraulic fluids can help meet your requirements.}

[Animated sequence]

{Screen goes white, and the Shell pecten appears, with contoured ripples on the background radiating from it, with piano music playing pecten notes.}

Shell Tellus S2 MX and Shell Tellus S2 VX

Give your equipment the extra protection it needs to reduce downtime and increase productivity with our long-life hydraulic fluids.

Find the right product for your application

Advanced

Shell Tellus S4 VK

Performance : Ultra low temperature

- Application

- Mobile

Advanced

Shell Tellus S4 VX

Performance : Ultra low temperature

- Application

- Mobile

Premium

Shell Tellus Zinc Free S3 MX (Formerly known as Shell Tellus S3 M/V )

Performance : Enhanced wear protection

Oil Properties : Zinc free

- Application

- Stationary

Premium

Shell Tellus Zinc Free S3 VX

Performance : Enhanced wear protection

Oil Properties : Zinc free

- Application

- Mobile

Premium

Shell Tellus S3 VS

Performance : Enhanced wear protection

Oil Properties : Anti stick slip

- Application

- Mobile

Mainstream

Shell Tellus S2 MX

Performance : Enhanced wear protection

Oil Properties : Standard

- Application

- Stationary

Shell Tellus S2 MA

Performance : Detergent

- Application

- Stationary

Shell Tellus S2 VA

Performance : Detergent

- Application

- Mobile

Shell PANOLIN S2 Hydraulic EAL

Performance : Biodegradable

- Application

- Mobile

Shell PANOLIN S4 HLP Synth

Performance : Biodegradable

- Application

- Mobile

Shell PANOLIN S4 HLP Synth EAL

Performance : Biodegradable

- Application

- Mobile

Discover the Shell Tellus range

Explore the full Shell Tellus range and discover the right high-performance hydraulic oil for your equipment operations.

More from Shell Lubricant Solutions

Discover our Services for Industrial Manufacturing

The Shell LubeAdvisor service is delivered through highly trained Shell technical staff consisting of office-based technical helpdesks and field-based lubrication engineers. In addition, there are a number of helpful and convenient tools for you to use, with the complete Shell LubeAdvisor service offering you a wealth of engineering, technical and application knowledge.