Click here to explore

Click here to explore the timeline

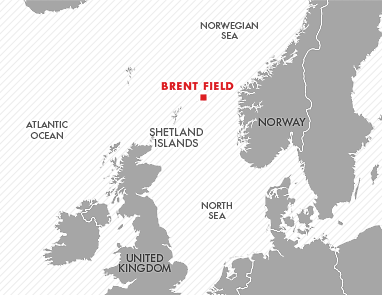

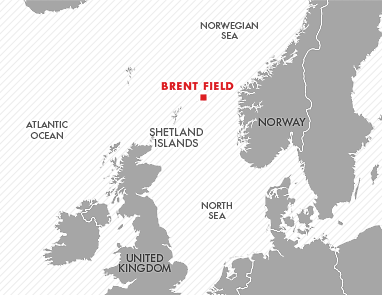

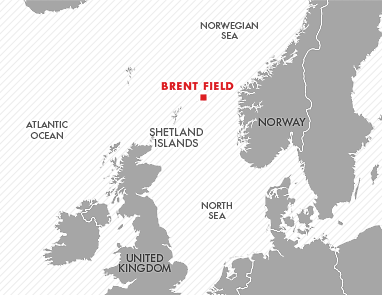

Brent Geography

The Brent Field is located 186km north east of the Shetland Islands

The Brent Field is located 186km north east of the Shetland Islands

1971

1976

1987

2001

2006

2014

Brent Field discovered

Brent Bravo is the first platform in the Brent Field to begin production

Brent produces its one billionth barrel of oil - this is enough to fuel 1.2 billion mid-sized cars

Brent Field celebrates its silver jubilee

Decommissioning project established

All wells on Brent Delta sealed and the platform is declared hydrocarbon-free

The Brent Field is located 186km north east of the Shetland Islands.

![]() Back to top

Back to top